Products

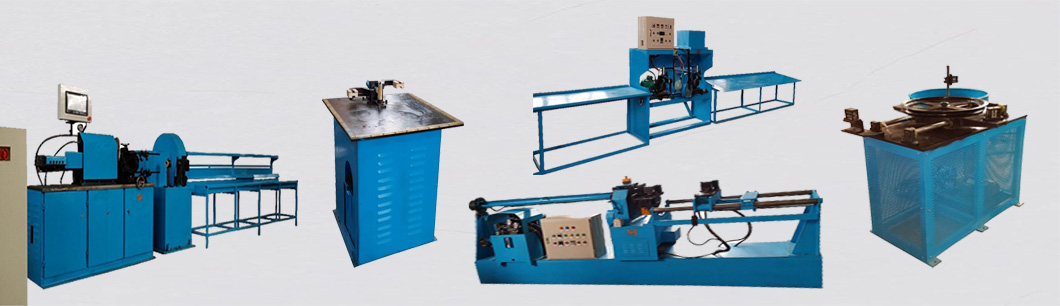

- NC Johnson Screen welding ...

- Wedge wire screen welding m...

- Internal Axial wire constru...

- Oil well wedge wire screen ...

- Well screen without base pi...

- Wedge Wire Cylindrical Scre...

- Stainless steel shaped wire...

- Bridge solt screen machine

- Preformed armor rods machin...

- Screen products

- Other machine

wire wrapped panel manufacturers

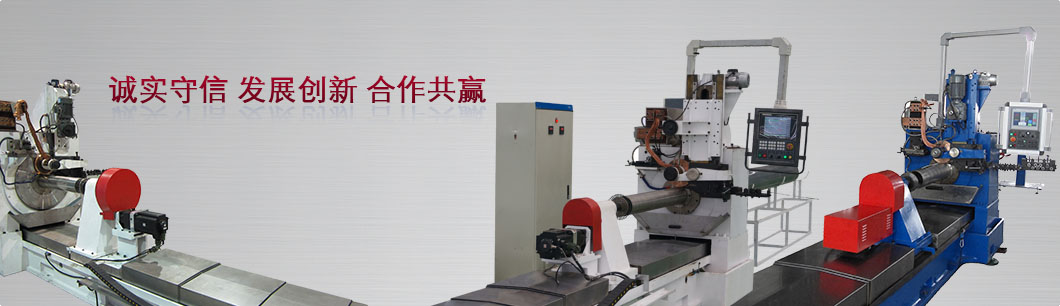

Welded wire screens, also known as Johnson tubes, Johnson screen tubes, and stainless steel screen tubes, are widely used in oil, gas and water well sand control industries worldwide. Their position in the wells industry is particularly prominent. The most widely used type of water filter screen.

Aokai screens adopt the world's most advanced full-wound welding process, applying special trapezoidal wire windings welded on a series of support wires arranged in a circular pattern. Full-scale welding ensures the product's strict continuous integrity, resulting in an ideal gap size and maximum capacity to withstand high pressures.

All production processes are produced by professional production staff using sophisticated and professional equipment. Product specifications and raw materials can be customized according to customer needs, all products are strictly in accordance with SY/T 5182-2008 standards for production inspection, to ensure product quality, thus ensuring the interests of customers, the most economical investment to obtain the highest production efficiency.

Product Features Features

1. The use of trapezoidal filaments creates Vee-shaped openings between screen gaps. This design is more efficient than other forms of product operation and ensures smooth water filtration.

2. The continuous winding of the trapezoidal wire forms a continuous high-density uniform gap on the support wire in a circumferential arrangement, which ensures the open area and non-obstruction of the screen, and avoids the high-density deposition of deposits, in order to increase the production efficiency and Extending the useful life of wells provides assurance.

3. Wire-wound and all supporting wires are welded together for durability and long life cycle.

4. According to the actual needs of the design of the support wire longitudinal arrangement and screen seam continuity gap, making the product has a higher compression performance.

5. The superior performance of the product has improved the working efficiency and life cycle of the well, making it a leader in water filtration equipment.