Products

- NC Johnson Screen welding ...

- Wedge wire screen welding m...

- Internal Axial wire constru...

- Oil well wedge wire screen ...

- Well screen without base pi...

- Wedge Wire Cylindrical Scre...

- Stainless steel shaped wire...

- Bridge solt screen machine

- Preformed armor rods machin...

- Screen products

- Other machine

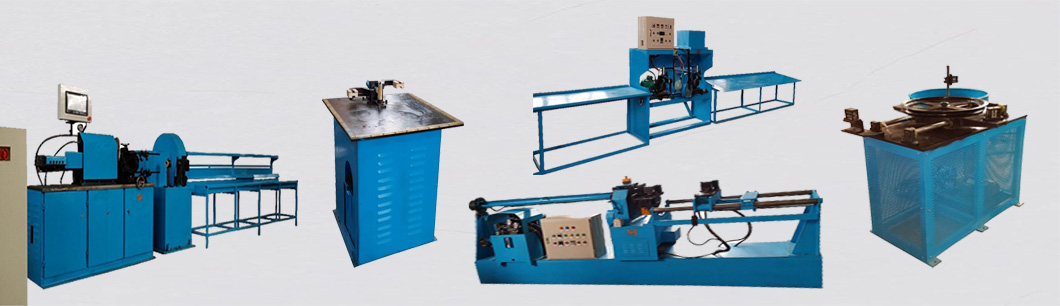

Automatic pre-twisted wire forming machine:

1. Suitable for the resistance of the clamp (aluminum wire, galvanized steel wire) and hanging wire clip (aluminum wire) processing. 2. Molding speed 0-1.5m / s, can form a diameter of 1.67-5.2mm (aluminum clad steel wire, galvanized steel wire), 1.78-9.27mm (aluminum alloy wire). 3. To meet the DL / T 763-2001 technical requirements, pre-twisted length of ± 2. 4. Feeding system disk rack for three: by the customer to provide aluminum package wire shaft, galvanized steel shaft and aluminum wire shaft of the specific size of the tray, if not provided by our conventional design. 5. This set of production line of high degree of automation, is an advanced mechanical and electrical integration equipment. In the automatic control, the molding process of a cabinet four machines, by the programmable controller (PLC) centralized linkage control line device, tensioning device, forming machine, cutting machine four sets of equipment. Touch screen man-machine interface, easy to operate, high stability, high yield. Equipment performance to the domestic first-class level.