Products

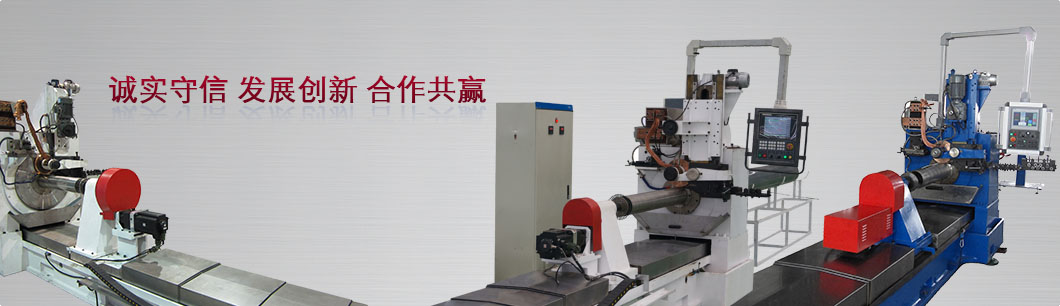

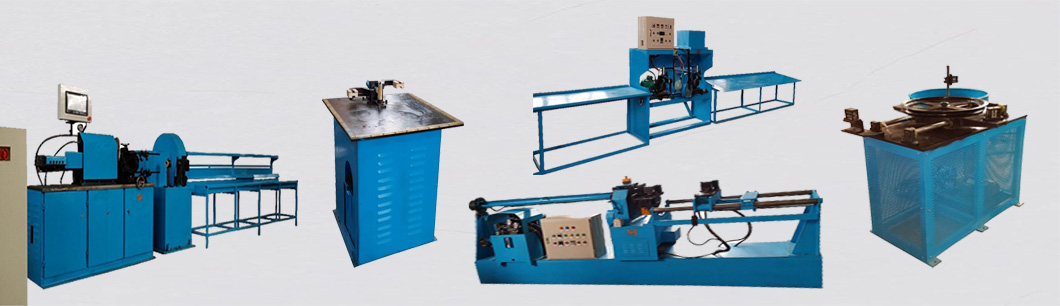

- NC Johnson Screen welding ...

- Wedge wire screen welding m...

- Internal Axial wire constru...

- Oil well wedge wire screen ...

- Well screen without base pi...

- Wedge Wire Cylindrical Scre...

- Stainless steel shaped wire...

- Bridge solt screen machine

- Preformed armor rods machin...

- Screen products

- Other machine

Steel straightening machine

1. Operators must wear helmets, gloves, wear rubber shoes.

2. Before the operation should check the straightening of the hoisting machine with the installation of the bearing, the components connected to the bolt, the anchor is solid, whether the rotation of a good grease, electric box wire is intact, no damage, then zero protection is reliable, electric shock protection action Sensitive, both ends of the fixture should be no damage.

3. Straightening bars along the length of 10 ~ 20m on both sides of the 2m area to prohibit the adoption, and set the protective baffle block, hanging safety signs.

4. Artificial lift 6,4 plate steel reel, should be 3 to 4 people with each other and some command.

5. Each time the length of steel bars, not more than 6m, both ends of the fixture clamped before the start of the hoist to straighten straight up about 60 ~ 100cm, immediately press the shutdown button to shut down, not down with the switch.

6. In the straight block is not fixed, the cover is not covered before the feed. Do not open the protective cover to adjust the gap.

7. After straightening should be relaxed and tightened to prevent the break when the injury wounding.

8. Operation in the manual lift straight after the reinforcement, not touch, touch high, low voltage power supply wire.

9. Work should always pay attention to the temperature of the bearing, such as more than 60 ℃, you must stop to identify the cause.

10. To straighten the work, are not allowed to keep people standing near the machine, when the steel plate on the fast finished, it is necessary to prevent the head of the injured wounds.

11. If the transmission part of the transmission is abnormal or abnormal sound, it should immediately shut down, cut off the power supply, report machine repair team, are not allowed to overhaul.

12. After the operation or in case of power failure, you should first cut off the power, lock the switch box

search keywords: wedge wire screen welding machine manufacturers